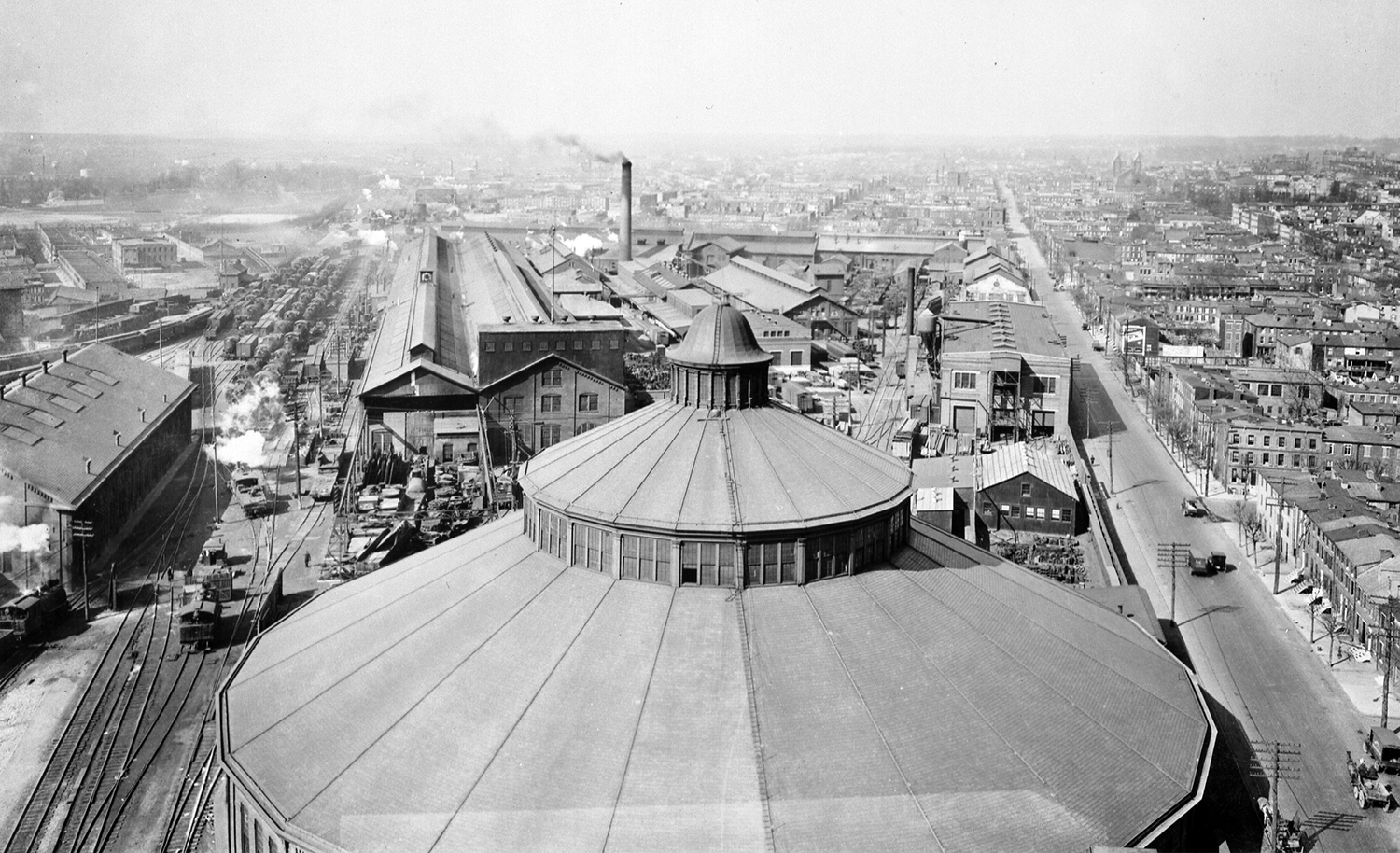

The Museum’s modern Restoration Facility opened in 2005 in response to the tragic collapse of the 1884 Roundhouse roof in February 2003.

The roof collapse caused tons of snow, slate, iron, and wood to fall on some of the premier pieces in the collection. Cost estimates coupled with the ongoing need to maintain and restore our operating fleet of diesel, steam engines, and historic rolling stock, led us to invest in a restoration facility which houses two museum departments: Restoration and Railroad Operations.

The 27,000 square foot shop is equipped with modern and historic tools and equipment. It contains 4 repair and maintenance tracks, a woodworking shop, a metal shop, a locomotive inspection pit, and fully enclosed paint booth capable of handling equipment up to 100’ in length.

The primary activities that take place in the shop are:

Research and documentation:

Primarily conducted by the museum’s archival and curatorial staff, this includes developing detailed historical background, including photographs and design documents, of equipment to be restored.

Assessment of locomotives:

The museum’s restoration shop staff and curatorial staff provide a detailed assessment, including photo documentation that defines preservation priorities and course of action.

Dismantling and conservation of original materials:

Led by experienced restorationists and informed by research, the locomotives and rolling stock are disassembled as necessary, documented, and conserved to protect original historic materials.

Inspection and restoration of components:

After dismantling, core elements of the equipment are documented and restored.

Reassembly of restored equipment:

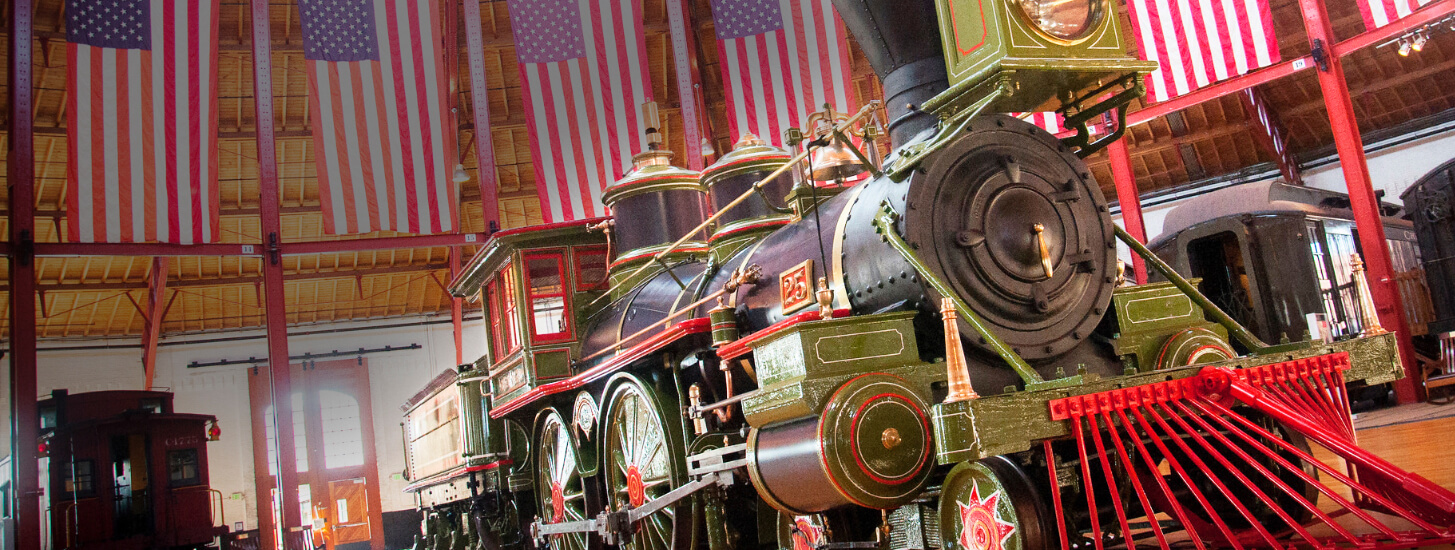

Using conserved original materials when possible the equipment is reassembled as historically accurate as possible.

Painting:

Paint analysis is conducted to determine color schemes and livery throughout the equipment’s active service.

Refinishing and detail work:

Based on research as well as the results of a historic paints analysis, the locomotives will be restored to their historic paint schemes.

Explore Other Areas of the Collection

Only at the B&O

Did You Know?

Andrew Jackson, in 1833, rode on the B&O Railroad, becoming the first US president to ride a train.